With the ability to reduce energy costs by up to 40%, metal roofing is a top choice for homeowners in search of the most energy-efficient roof.

Reports from the EPA, studies by the U.S. Department of Energy, and nearly every article on Google consistently name metal roofing as one of the most energy-efficient roofing materials on the market.

But for homeowners who place energy efficiency at the top of their priority list, it’s important to know that the exceptional energy efficiency of metal roofing can be enhanced even further with advanced underlayments, installation methods, and cutting-edge materials.

If maximum energy efficiency is your target, here’s what you need to know to push the energy efficiency of metal roofing to its peak.

- How is the Energy Efficiency of a Roof Measured?

- Upgrade from Below the Roof: Underlayments that Boost Energy Efficiency

- More Air, More Efficiency: Installation Methods to Maximize Airflow and Ventilation

How is the Energy Efficiency of a Roof Measured?

Energy efficiency is measured differently across various products and industries. For example, refrigerators are often assessed for energy efficiency by how much electricity they use relative to their size and cooling capacity.

In roofing, energy efficiency is measured by three key physical characteristics, collectively known as thermal performance.

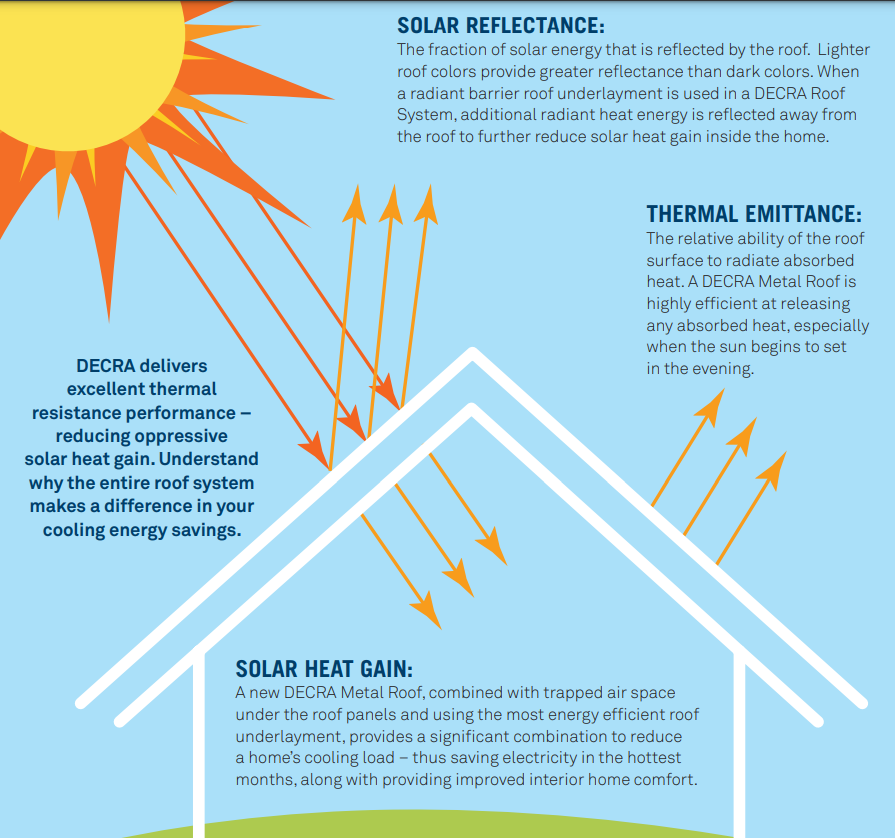

Thermal resistance, also known as R-value, is the roof's ability to resist heat transfer. The concept of thermal resistance is similar to how a thermos or cooler helps keep drinks warm or cold by minimizing heat exchange. For example, a metal roof acts similarly to a cooler's outer shell by reflecting sunlight to keep the interior building cooler. Conversely, an asphalt roof absorbs heat, much like a sponge, warming the space below. Thermal resistance is typically measured as an R-value, and roofs with higher R-values mean they are better at insulating temperatures.

Emissivity refers to how well a roof can release absorbed heat back into the atmosphere. Roofing materials with high emissivity can cool down faster than those with low emissivity. For example, think of a metal car hood that becomes hot under the sun and from the engine below. When the car is parked, and the engine is turned off, the metal quickly becomes cool to the touch. Now, think of how asphalt pavement retains heat long after the sun has set. The same is true for metal roofs and asphalt shingle roofs. The high emissivity of a metal roof will help keep a building much cooler than an asphalt shingle roof that radiates heat down into the building below, even after the sun has set.

Reflectivity refers to how well a roofing material is able to reflect sunlight and heat away from the building. Imagine a mirror reflecting the sun's rays up and away from a building–that’s how a highly reflective roof works. Just like a mirror, a metal roof reflects the sun’s energy and heat away from the building. On the other hand, an asphalt shingle roof is much like wearing dark clothing on a hot day and will absorb–rather than reflect–more sunlight and heat.

- Advanced underlayments that enhance the roof's thermal resistance by reducing heat transfer between the roof and the building interior.

- Installation methods that increase the airspace beneath the roofing improve the roof's ability to emit heat, reduce heat accumulation, and promote more efficient temperature regulation inside the building.

Here’s how these upgrades supercharge the energy efficiency of a metal roof.

Upgrade from Below the Roof: Advanced Underlayments that Reduce Heat Transfer

Underlayment is part of the complete roofing system that is installed between the roof deck below and the roofing material above. The purpose of underlayment is to provide a secondary layer of protection against water penetration and help to prevent leaks.

The three most common types of underlayment for metal roofing are asphalt-saturated felt, paper, synthetic, and peel-and-stick.

Similar to upgrading standard tires to high-performance tires on a new car, underlayment upgrades can help reduce heat transfer and boost the energy efficiency of a metal roof.

Asphalt-saturated felt, also known as tar paper, is the standard and most common type of underlayment. It provides the required protection and works just fine for most roofing projects.

However, while standard roof underlayments do protect against water penetration, they aren’t very effective at preventing heat from passing through them (a.k.a. keeping heat out during summer or keeping warmth in during winter). This is where more specialized underlayments, such as radiant barrier underlayments, come into play.

Upgrading to an advanced synthetic underlayment with a radiant barrier can substantially enhance the energy efficiency of a metal roof, much like high-performance tires provide better traction and efficiency for a car.

Radiant barrier underlayments provide more than just the basic functions of a typical synthetic underlayment–such as water resistance and enhanced durability–they also reflect solar heat and help regulate the building's temperature.

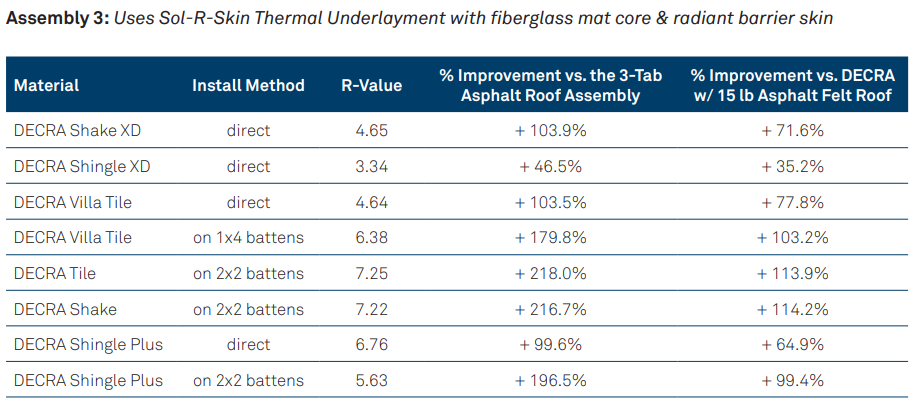

For example, an independent study by R&D Engineering found replacing felt underlayment with a radiant barrier type, made of synthetic fabric combined with an aluminum foil-reflective surface, significantly improved thermal efficiency. The increase was measured as high as 113.9% when installed on battens and 77.8% when installed directly to the roof (read the full study here).

It’s important to note that a radiant barrier underlayment requires air space above for it to be effective. All DECRA Metal Roofing panels provide that minimum average air space, regardless if they are installed on battens or directly to the roof.

Keep reading to learn how this air space is critical to the energy efficiency of a roof.

More Air, More Efficiency: Installation Methods that Maximize Airflow and Ventilation

Airflow and ventilation are critical to a roof's energy efficiency because they allow hot air to escape and cooler air to come in. This lessens the need for air conditioning in the summer by preventing heat buildup under the roof. In the winter, it keeps the roof temperature consistent and reduces the risk of ice dams.

The manner in which a roofing material is installed can impact how much air flows through and ventilates the roof, which in turn impacts the overall energy efficiency of the building.

There are two ways in which metal roofing is installed:

- Batten installations involve laying a lattice of wooden or metal battens across the existing roof deck before attaching the metal roofing panels. Once the metal roofing panels are attached to the 2x2 wood batten grid, they are raised off the roof deck to create continuous airspace.

- Direct-to-deck installations are just what the name implies: metal roofing panels that are installed directly onto the roof deck without an intervening structure.

> > > Learn more about batten vs. direct-to-deck installations here.

One key benefit of a batten installation when it comes to energy efficiency is the additional airspace created by raising the roofing material off of the underlying deck.

One key benefit of a batten installation when it comes to energy efficiency is the additional airspace created by raising the roofing material off of the underlying deck.

Choosing a roofing material that can be installed on battens is the way to go for homeowners looking to maximize energy efficiency. DECRA Metal Roofing offers two profiles that can be installed on battens: DECRA Tile and DECRA Shake.

While batten installations offer an added layer of ventilation and energy efficiency, metal roofs installed using the direct-to-deck method still provide significant energy-saving benefits due to their emissive properties, especially when selecting a lighter color roof for greater heat-reflective properties.

DECRA Metal Roofing profiles that are installed direct-to-deck–such as DECRA Villa Tile, DECRA Shingle XD, and DECRA Shake XD–are engineered to provide adequate airspace to ensure proper airflow and above-roof sheathing ventilation.

Oak Ridge National Laboratory (ORNL), an acclaimed laboratory dedicated to research for the U.S. Department of Energy, confirmed this in a recent study, “The Effects of Infrared-Blocking Pigments and Deck Venting on Stone-Coated Metal Residential Roofs.”

ORNL tested the thermal performance of DECRA Metal Roofing profiles installed on a variety of test roofs over an extensive testing period that ran through the natural cycles of winter and summer seasons.

DECRA Tile, which is installed on battens, and DECRA Shake XD, which is installed direct-to-deck, were used in the study.

The study confirmed that DECRA roofs installed direct-to-deck enhanced energy efficiency due to the solar reflective and emissivity properties provided by all DECRA Metal Roofing profiles.

What does this mean for homeowners looking to supercharge energy efficiency?

The study confirmed that irrespective of how a DECRA metal roof is installed, all DECRA roofing profiles contribute positively to energy efficiency–though installing on battens will provide the maximum benefit (read the full study here).

Ready to Supercharge Energy Efficiency with DECRA Metal Roofing?

If you’re looking for a roof that takes energy efficiency to the next level, you’re looking for a DECRA roof.

With a wide variety of colors, textures, and styles to choose from, DECRA can replicate the look of traditional roofing materials like asphalt shingles, clay tiles, and wood shakes–without sacrificing durability, longevity, or energy efficiency.

As the original stone-coated metal roofing manufacturer since 1957, DECRA roofs have passed the test of time and endured with excellence in some of the world’s harshest climates.

DECRA continuously tests our products with independent labs to ensure the quality DECRA is known for is present in each panel we produce. As a testament to our commitment to quality, all our roofs come standard with one of the industry's most comprehensive Lifetime Limited Warranties for residential roofing.

Ready to see and feel the DECRA difference? Order a complimentary sample today.

Editor's Note: This blog was originally published in June of 2020, but has been updated with relevant content.