Synthetic roofing refers to roofing materials created from man-made compounds, as opposed to natural materials, such as wood or clay. Examples of synthetic roofing materials include rubber (EPDM) and plastic polymer roofing.

Although the terms synthetic roofing and composite roofing are often used interchangeably, they aren't the same.

Composite roofing refers to roofing materials that are a blend of different materials, which can be a mixture of both synthetic and natural elements. While composite roofing is also considered synthetic roofing because it’s man-made, not all synthetic roofing materials are composites; some may be made from a single type of material.

For example, asphalt shingles, which are made up of a mat (often fiberglass), asphalt, and mineral granules, are a type of composite roofing material. They're not purely synthetic, as they include natural asphalt, but they're often grouped with synthetic roofing because they’re manufactured and do not consist solely of natural materials.

Synthetic roofing materials are often considered by homeowners searching for the perfect blend of durability and aesthetic appeal. Yet, there's another contender that often comes into the picture when seeking a long-lasting and cost-effective residential roofing solution: metal roofing.

In this article, we'll dive deeper into the specifics of synthetic roofing and metal roofing to help homeowners make an informed decision. Keep reading to learn:

- Synthetic Roofing vs. Metal Roofing: Which is More Durable?

- Cost Comparison of Synthetic Roofing vs. Metal Roofing

- Aesthetic Appeal: Comparing Styles of Synthetic Roofing and Metal Roofing

- Which is Better: Synthetic Roofing or Metal Roofing?

Metal Roofing vs. Synthetic Roofing: Which is More Durable?

As mentioned earlier, synthetic roofing involves materials like EPDM, an M-class rubber, which has excellent resistance to heat, UV radiation, and weathering.

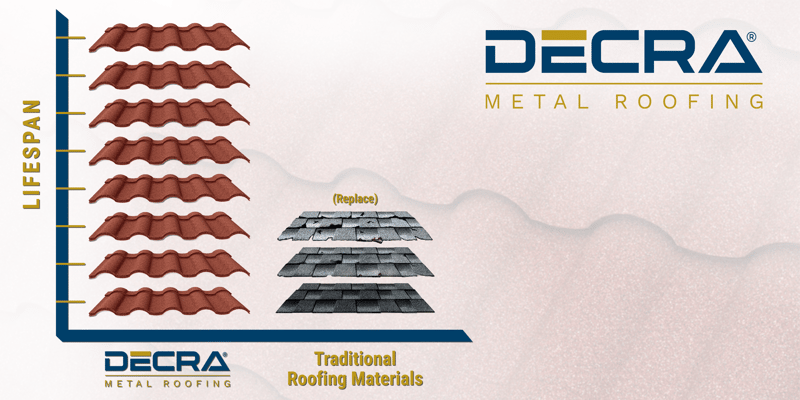

However, even premium synthetic roofing materials need to be replaced as often as every 20 years. This shorter life expectancy can be attributed to lower tensile strength and greater thermal expansion, which cause increased stress over time.

Metal roofing, on the other hand, can easily last for 70 years or longer.

The high tensile strength of metal and its inherent resistance to various elements, such as wind, fire, and hail, make it one of the best types of roofing when it comes to durability and longevity.

Cost Comparison of Metal Roofing vs. Synthetic Roofing

The initial cost, as well as the long-term costs of maintenance and potential replacement, are critical considerations.

Metal roofing tends to have a higher upfront cost compared to synthetic roofing, but requires less maintenance and has a longer lifespan, making it more cost-effective in the long run.

When comparing metal roofing to synthetic roofing in terms of return on investment (ROI), several factors can make metal roofing the more valuable option, including:

- Longevity: The lifespan of a metal roof is two to three times longer than synthetic roofing materials.

- Durability: Metal roofs are well-known as one of the strongest roofing materials on the market.

- Energy Efficiency: Metal roofs are extremely energy efficient and reflect heat up and away from the home, which can reduce cooling costs by as much as 40%.

- Home Value: Due to their durability, longevity, and energy efficiency, metal roofs can increase the resale value of a home by up to 6%.

- Insurance Benefits: The durability and longevity of metal roofing can reduce homeowners' insurance premiums by up to 35%.

While synthetic roofs can also offer some of these benefits, the overall durability, lifespan, and energy efficiency of metal roofing often make it a more cost-effective choice.

Additionally, the strength and durability of metal roofing are often reflected in manufacturers’ warranties. It's common for metal roofing materials to come with warranties that last 50 years or longer. Premium metal roofing manufacturers even offer a Lifetime Limited Warranty on their products.

The warranties for synthetic roofing materials can vary significantly based on the type of synthetic material used and the manufacturer. Synthetic roofing warranties can range from 20 to 50 years, however, as synthetic roofing is a relatively newer product compared to metal roofing, some warranties might be limited due to less historical data on long-term durability.

Tip: A key consideration when comparing warranties is to look not just at the length of the warranty, but what it specifically covers, any maintenance conditions, and whether it's prorated or non-prorated. Also, keep in mind that the company needs to be in business for the warranty to be valid, so consider the manufacturer's reputation and the amount of time they’ve been in business.

Aesthetic Appeal: Comparing Styles of Synthetic Roofing and Metal Roofing

Both metal roofs and synthetic roofs can adapt to a wide range of architectural styles.

Metal roofing comes in a wide variety of styles and colors. Different metals can also influence the aesthetic. For example, copper develops a patina over time, changing from a bright, shiny penny color to a distinctive green.

Standing seam panels offer a modern, clean look with long, minimalistic lines. Corrugated panels, on the other hand, have a more industrial aesthetic.

Stone-coated metal roofs are made from high-grade steel sheets that are coated with natural stone granules. The stone-coating process results in a metal roof that provides the same aesthetics of traditional roofing materials–such as asphalt shingles, clay tile and wood shakes.

There really isn’t a winner in this category since the decision between the two often comes down to your personal preference and the specific design of your home.

Which is Better: Synthetic Roofing or Metal Roofing?

In the end, every homeowner's situation is unique and it's important to consider all factors and consult with a professional roofing contractor.

With that in mind, synthetic roofing is often ideal for homeowners who:

Want Durable Materials with Lower Cost: While they may not last as long as metal roofs, high-quality synthetic roofs still offer impressive durability at a potentially lower price point.

Live in Moderate Climate: Synthetic roofs are durable, but they might not be as resistant to severe weather conditions as metal roofs.

Metal roofing is often the best type of roofing for homeowners who:

Want a high ROI: While metal roofing can be more expensive upfront than other types of roofing, the longevity and low maintenance of metal roofs often make them cost-effective in the long run.

Are Eco-Conscious: Metal roofs are one of the most environmentally-friendly types of roofing since they’re made from sustainable materials and can be completely recycled at the end of their life.

Live in Harsh Weather Conditions: Metal roofs have inherent strength and can endure everything from high winds to hail and:

- Fire: As a non-combustible material, metal roofs have the highest-possible Class 4 fire rating.

- Earthquakes: Lightweight metal roofing can withstand earthquakes and provide critical reinforcing sheer strength to the home.

- Salt Air and Humid Climates: Metal roofs are resistant to rust and oxidation.

- Snow: Non-porous metal roofs can prevent ice dams and withstand repeated freeze and thaw cycles.

Ready to experience the DECRA difference? Experience the strength and style that only stone-coated metal roofing can provide by requesting a complimentary sample today.

Editor's Note: This blog was originally published in June 2020, but has been updated with relevant information.